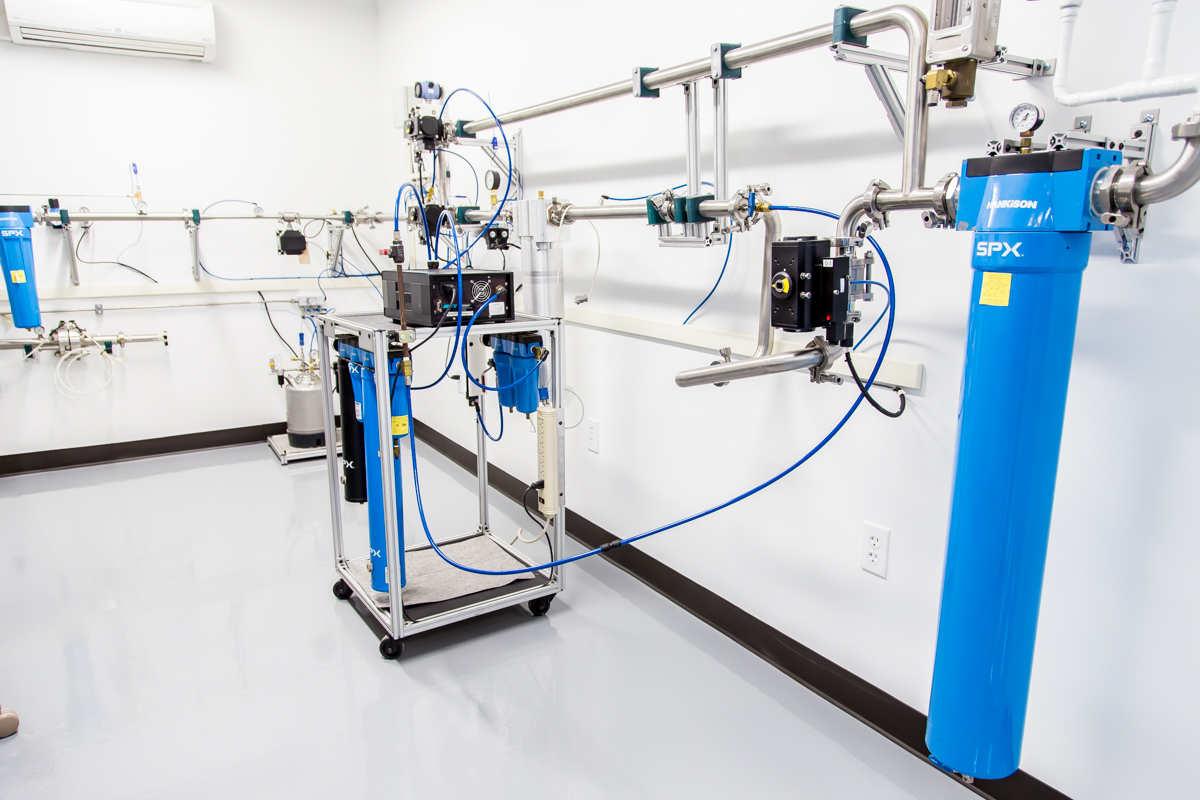

Compressed air is a key component in many manufacturing processes. Since it plays a major role in the function of many types of equipment, it is important that compressed air be both clean and dry.

Protects Against Contaminants

With entire manufacturing processes relying on the quality of compressed air the importance of Donaldson compressed air filters cannot be overlooked. Unfiltered compressed air spreads contaminants like dirt, oil, and water throughout the equipment. These contaminants may cause pipe corrosion or other equipment malfunction. Filters extend the life of equipment by capturing these polluting agents before they become a problem.

Protects Against Pressure Loss

Manufacturers use compressed air for a reason – it improves equipment performance and efficiency. Its power comes from the pressure produced by compressing the air. This means that even the slightest decrease in air pressure can slow or halt production, leading to unnecessary delays and maintenance costs. Proper filtration ensures that air pressure will remain at a consistent level and decreases or eliminates the risk of pressure loss.

Protects Against Moisture

Moisture is the nemesis of manufacturing equipment, and, as a byproduct of compressed air, filtration is necessary to keep the airflow dry and protect against condensation. Like other contaminants, water can lead to equipment corrosion, rust, and higher maintenance costs. Moisture also attracts bacteria and viruses, which could lead to product recall and loss of faith in the product or manufacturer.

Protects the Bottom Line

By protecting against corrosion, contaminants, pressure loss and moisture compressed air filtration decreases operating costs by extending the life of the equipment and eliminating the unnecessary maintenance costs and downtime caused by inadequate filtration. The increase in efficiency and reliability has a significant positive impact on the bottom line.

There is no doubt a quality air filtration system saves time and money while improving efficiency and productivity in manufacturing plants that use compressed air for their processes.